Load Capacity C

C is the load capacity of the gearbox, this is determined via several variable factors.

- Number of hours per day the unit is operated

- Number of starts per hour

- Load Type see below

Load Type

- Duty I = Smooth operation, small or light jolts

- Duty II = Uneven operation, average jolts

- Duty III = Uneven operation, severe jolts and/or alternating load

It is important to select the correct load capacity C of the gearbox as this ensures the gearbox is robust enough to give its full service life, incorrect selection could result in premature failure of the gearbox or oversizing with a larger and more expensive gearbox being selected than required.

As a rough guide with 8 hours per day running and no more than 10 starts per hour with correct oil selection and ambient temperature, then a selection of C as below would be suitable.

- Duty I 1.0 to 1.4

- Duty II 1.4 to 1.6

- Duty III 1.6 to 1.8

For a full and technical explanation of load capacity C please see below or call Transdrive for further advice.

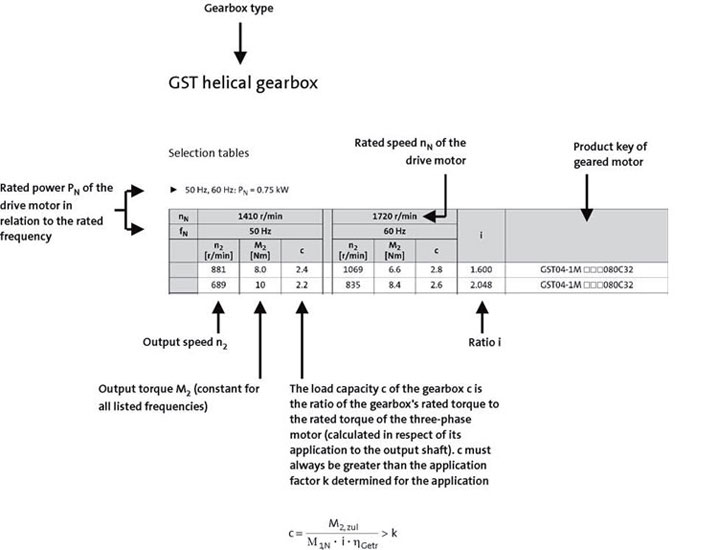

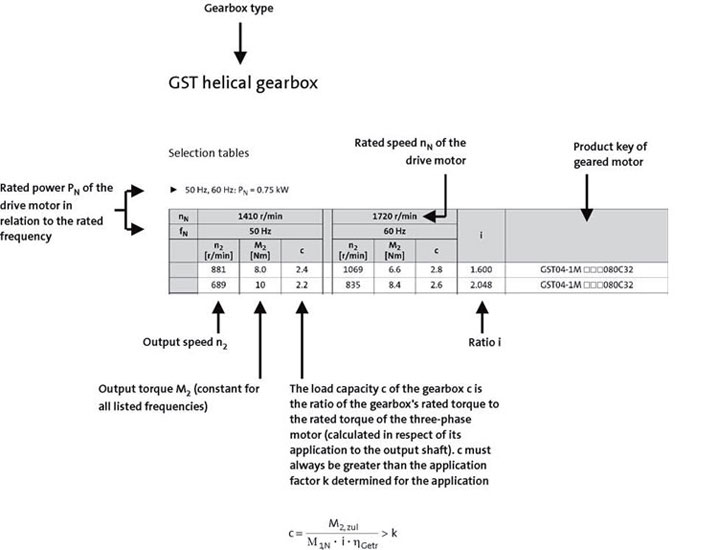

Load Capacity and application Factor

Load capacity of gearbox

Rated value for the load capacity of Lenze geared motors

- c is the ratio of the permissible rated torque of the gearbox to the rated torque supplied by the drive component (eg. The build in Lenze motor)

- The value of c must always be greater than the application factor k calculated for the application.

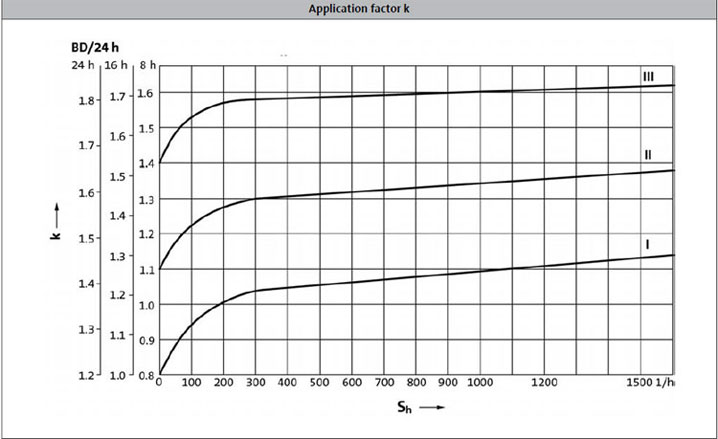

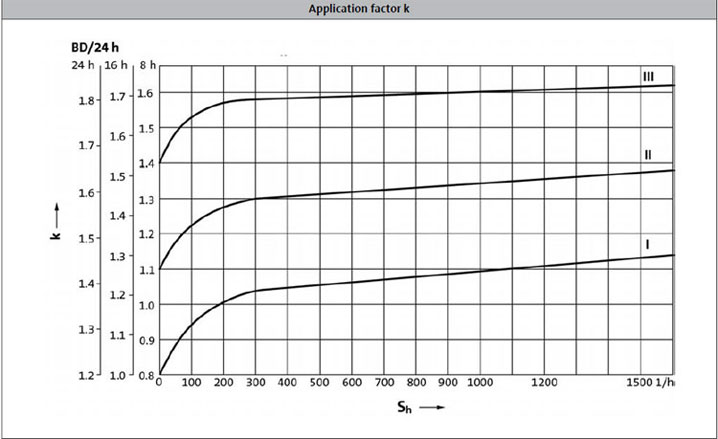

Application factor k (according to DIN 3990)

Take into account the influence of temporally variable loads which are actually present during the atnticipated operating time of gearboxes and geared motors.

k is determined by:-

- the type of load

- the load intensity

- temporal influences

| Duty class | Load type |

|---|

| I | Smooth operation, small or light jolts |

| II | Uneven operation, average jolts |

| III | Uneven operation, severe jolts and/or alternating load |

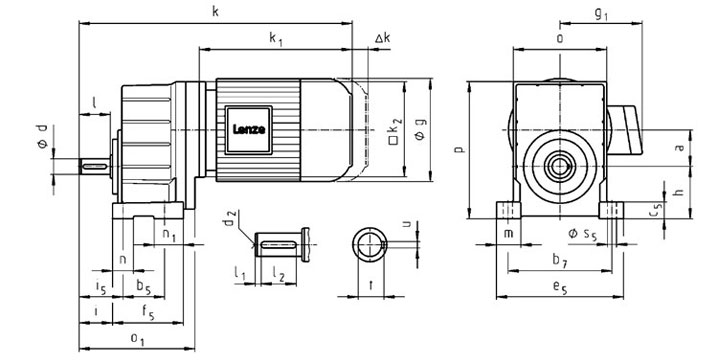

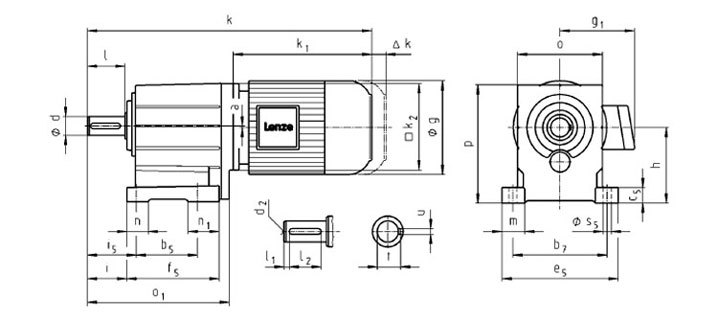

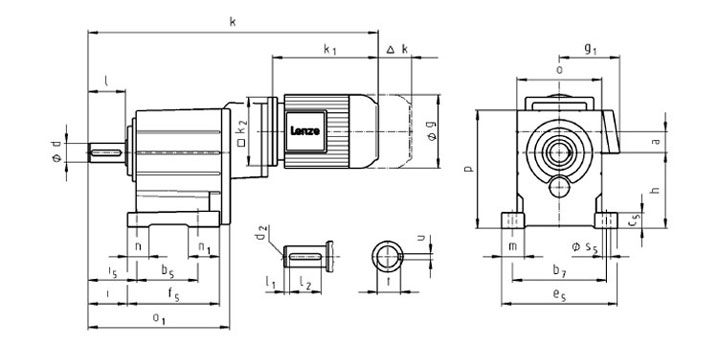

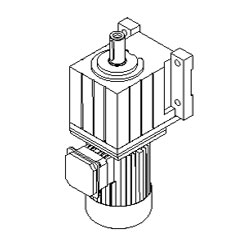

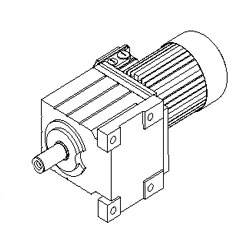

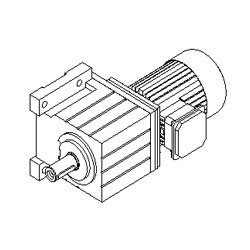

Lenze GST Geared Motors

Lenze GST Geared Motors